From Rusty Returns to Flawless Seals: The Science Behind Food-Grade Capping

Are you constantly facing customer complaints about rusted lids and leakage after filling? Or dealing with packaging deformation and product returns post high-temperature sterilization? As experts in food-grade glass packaging container solutions, we fully understand the dual challenges of quality preservation and packaging compatibility during high-temperature sterilization. Below we analyze common pain points and explain key considerations for mainstream sterilization methods and packaging selection to help you achieve safe, efficient production.

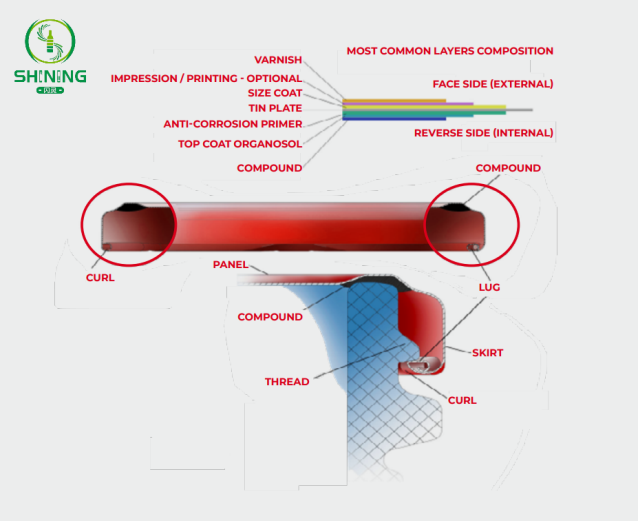

1. What Are Tinplate Lids Made Of

Twist-Off closures are primarily made from doublesided tinplate. This metal closure with a compound inner lining, is designed to fit various glass finishes under various processing conditions. The closure, if properly used, is designed to ensure packaging integrity throughout the packaging’s lifecycle and to keep the product safe. In respect of the intended food product contact, sheets are lacquered on the reverse side with anti corrosion primer, as well as an adhesion-promoting Topcoat layer (organosol BPA NI). Depending on the decorative aspects, the sheets are printed on the face side with one or more layers of printing ink and finished with a clear varnish.

These semi finished sheets, called “finish plate”, is cut in circular blanks. The cut edges are open and unpainted. In the forming process that follows, these edges are carefully curled, lugs are formed, and the closure receives its final shape. In the last manufacturing step, the sealant, which produces the gas-and liquid-proof packaging system, is injected into the closure and finally dried in a curing oven. The tinplate used is of varying thickness and hardness according to the closure type and its intended application. Closure types with the requirement to withstand high mechanical stress during heat treatment are generally produced with thicker material. Usually, the thickness of sheets used for Twist-Off closures is in the range between 0.16mm – 0.18mm.

2. Causes of Tinplate Lid Rust

Rusting of tinplate lids is the result of electrochemical corrosion of the metal substrate (iron) when exposed to an oxidising environment, the specific causes of which can be classified as follows:

| Cause Type | Specific Manifestations | Associated Scenarios |

| Physical Damage | Mechanical friction or collision during transport, screwing of lids leads to breakage of the tin layer and exposure of the iron substrate. | All sterilization methods, especially pressurized steam sterilization (high risk of cap deformation) |

| Chemical Corrosion | Direct corrosion of the tin layer or coating by acidic/alkaline components, damaging the protective layer (e.g. highly acidic sauces pH ≤ 4.5). | High temperature water bath sterilisation (acidic + high temperature), pasteurisation (prolonged exposure to active ingredients). |

| Electrochemical Corrosion | Lid in contact with glass bottle mouth forms a potential difference and accelerates localised corrosion (e.g. when salt is present). | Sauces with high salt content (e.g. bean paste), storage in humid environments. |

| High temperature and high humidity oxidation | Not thoroughly dried after filling, water beads remain in the gap between lid and bottle mouth, long-term contact with the substrate iron triggering oxidation | Inadequate cooling after high temperature sterilisation, low efficiency of drying equipment |

| Coating Damage | The internal anti-corrosion coating of the lid (e.g., organosolvents, primer) is scratched in the process of transporting, filling, or unscrewing the cap, resulting in the exposure of the substrate iron | The machine unscrewing the cap is too strong resulting in the rolled-up edge being flipped out, and the coating is scratched by the burr on the mouth of the glass bottle |

In order to avoid customers encounter rust problems in the process of use, Shining Glass will ask the food factory (or sauce factory, filling factory) the following information before the production of lids, and then we will suggest customers to match the different filler according to the different contents of the customer's filling:

· Product?

· Product contains free oil?

· Will product have a thermal treatment? Which one?

· Closure is manual or by capping machine?

· Has customer the chance to pre-heat lids or use steam flow?

· Is Flip safety button requested?

· Does product contain aggressive elements?

We can find the correct type by matching the above packaging conditions in the following chart.

|

Product Catalogue |

Contains fat and /or oil |

Thermal Treatment |

Compliance with oil |

Compound |

Notes |

|

Honey, jams, cfruit conserves, dry food, products w/o oil |

No |

None |

Not Necessary |

C&M |

Cold Closing |

|

Jams to be pasteurized |

No |

PASTEURIZATION |

EL-EF-ENI but not necessary |

PAST |

|

|

Marinated vegetables or preserved in oil, other products w oil |

Yes |

PASTEURIZATION |

EL-EF-ENI |

PAST |

|

|

Meat, fish, legumes, truffle, foodstuff with high bacterial load - preserved in oil |

Yes |

STERILIZATION |

EL-EF-ENI |

STER |

|

|

Products w relevant contents of oil and long expiry date (shelf life) |

Yes |

PASTEURIZATION OR STERILIZATION |

PVC FREE |

PAST OR STER |

|

|

AGGRESSIVE PRODUCTS (W AND W/O OIL) |

RISKY COMPONENTS (AGGRESSIVE) |

THERMAL TREATMENT |

COMPLIANCE WITH OIL |

COMPOUND |

NOTES |

|

Onions, gherkins, pickles of any kind and vegetables in vinegar, asparagus |

SO2 > 50ppm pH > 4,0 Salt > 10% Chloride and/or NaCl > 50ppm |

PASTEURIZATION OR STERILIZATION (depending on each product) |

EL-EF-ENI or PVCFREE |

PAST O STER |

Need specific protection inside, production on demand. To be verified before ordering. |

3. Targeted Solutions

Based on the causes of rusting, combined with different sterilisation methods and food characteristics, the following solutions have been developed:

Filling

Choosing a tinplate cap from Shining Packaging is not just about choosing a product, it's about choosing a complete rust prevention solution!

We provide ‘one-stop service’ from cap customisation, process optimisation to after-sales support, helping you to easily cope with production problems, so that every bottle of product can stand the test of time and consumers.

�� Inquiry Now:Get your FREE anti-rust solution + samples!

�� Hot Lines:+86 180 2416 0508 / WhatsApp: +86 137 2499 2065

-

The Ultimate Showdown of Bird’s Nest Packaging: PT Cap vs. Tinplate Cap vs. Aluminum Cap

How to choose the perfect sealing cap for bird’s-nest packaging? Which comes out on top—PT-lined caps, tinplate caps, or aluminum screw caps? New to the industry and afraid of pitfalls? Seasoned pros still plagued by leaks? This article offers a deep dive into the performance, cost, and ideal applications of these three cap types, tackling the industry’s toughest challenges and helping you “crown” your product with the right cap—balancing quality and profit!

넶5 2025-04-28 -

From Rusty Returns to Flawless Seals: The Science Behind Food-Grade Capping

Are you constantly facing customer complaints about rusted lids and leakage after filling? Or dealing with packaging deformation and product returns post high-temperature sterilization? As experts in food-grade glass packaging container solutions, we fully understand the dual challenges of quality preservation and packaging compatibility during high-temperature sterilization.

넶11 2025-04-08 -

Why Embossing & Debossing Add Exceptional Commercial Value to Glass Bottles

In the packaging industry, first impressions determine whether consumers pick up your product. In an era where visual designs increasingly blend together, tactile experience has become a hidden weapon for brands to stand out. Embossing and debossing techniques create irreplaceable added value by giving glass packaging unique three-dimensional textures. At Shining Glass, we believe that packaging is not just a container—it’s a medium for brands to connect with users.

넶12 2025-03-21 -

Glass Bottle Selection Guide for Capsule and Pill Packaging

In the pharmaceutical and nutraceutical industries, packaging plays a critical role in ensuring product safety, efficacy, and shelf life. This guide provides a comprehensive overview of glass bottle selection for capsule and pill packaging, tailored for retailers, wholesalers, and distributors. Learn why glass is the preferred material, how to choose the right bottle size, and how Shining Glass can be your trusted partner in pharmaceutical packaging.

넶4 2025-03-11 -

The Genius of Texture: How Beverage Brands Use Orange Peel Patterns to Stand Out

To All Brand Owners, Designers, and Beverage Enthusiasts: Let's Talk About the Orange Peel Texture on Drink Bottles!

Yes, that bumpy, dimpled texture on your favorite drink bottle isn’t just a random design choice. If you thought it was merely decorative, think again! This unassuming feature is the “hexagonal warrior” of the beverage packaging world, a true hidden champion of industrial design that seamlessly blends functionality, aesthetics, and cost-efficiency.넶6 2025-02-28