The Truth About Glass Container Twist-off Lug Cap Sealing

The Truth About Glass Bottle Cap (Twist-off Lug Cap)Sealing, Do You Really Know?

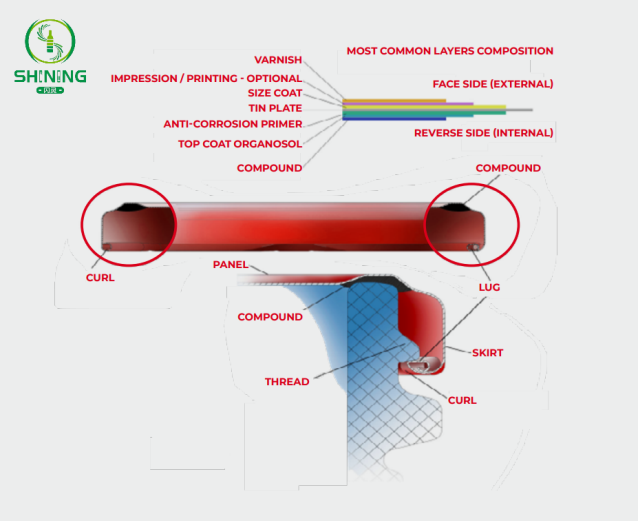

Tinplate caps, commonly known as Twist-off Lug Caps, are ubiquitous in the packaging industry, safeguarding the freshness and integrity of various food and beverage products. The sealing process of these caps is a fascinating fusion of technology and engineering, governed by principles that go beyond mere mechanical tightness. Let's delve into the intricate workings of tinplate cap sealing, shedding light on its core mechanisms and dispelling misconceptions.

1. Glue Injection:

At the heart of tinplate cap sealing lies the strategic injection of adhesive glue inside the lid structure. This adhesive serves as the primary sealing agent, creating an airtight barrier between the lid and the container. The application of glue is meticulously controlled to ensure uniform coverage, optimizing the sealing performance across different lid sizes and shapes. The adhesive undergoes curing processes, further enhancing its bonding strength and durability.

2. Beyond Mechanical Tightness:

Contrary to popular belief, the effectiveness of tinplate cap sealing isn't solely determined by the tightness of the lid's jaws. While some pressure is necessary to establish a secure seal, excessive force can lead to adverse outcomes such as deformation of the lid or damage to the container threads. Instead, manufacturers prioritize precision over brute force, ensuring that the sealing mechanism strikes the perfect balance between snugness and flexibility.

3. Principles of Twist-off Lug Cap Sealing:

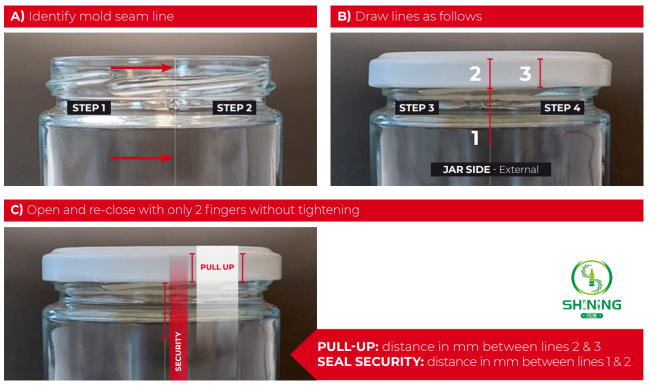

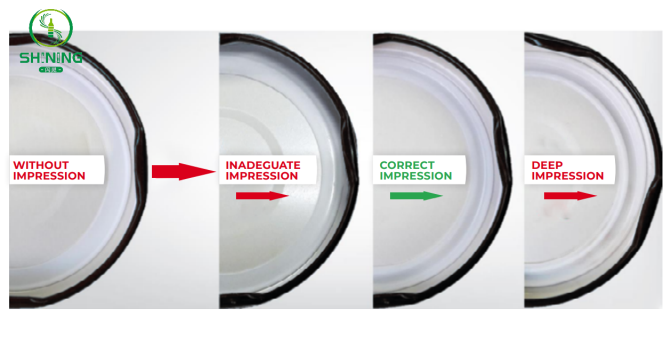

The compound impression shows how it gets shaped, in order to stick to mouth glass profile, then sealing after cooling and stabilization. The sign can be deeper in compounds with food-grade PVC, and less deep in the PVC Free ones that, for their own properties, are harder, for this reason pre-heating and impression check are important tests. Impression must be visible and continuous along the entire circumference, deep enough to have a proper contact surface, but not too deep to reach metal. If such conditions are not respected, a corrective action will be necessary. If impression is shallow, usually it needs to increase pre-heating and, if not enough, put additional pressure on the spring inside the closing section of the machine; in case of too deep impression, go for the contrary actions. To make it simple, it’s easy to find out how a correct impression is, from the pictures below

4. Quality Assurance Measures:

To uphold stringent quality standards, manufacturers implement rigorous testing and inspection protocols throughout the sealing process. Advanced technologies such as visual inspection systems, pressure testing equipment, and leak detection devices are employed to verify the integrity of sealed packages. Any deviations from specified sealing parameters are promptly addressed, ensuring that every tinplate cap meets the highest standards of performance and reliability.

5. Contact with Shining:

By embracing innovative techniques and refining sealing processes, Shining continue to elevate the reliability and efficiency of tinplate cap sealing, meeting the evolving needs of consumers and industries alike. As we unravel the complexities of tinplate cap sealing, we gain a deeper appreciation for the precision and expertise that underpin this essential aspect of modern packaging technology.

Suscribe, share with friends and leave your comments to us.

-

Glass Bottle Selection Guide for Capsule and Pill Packaging

In the pharmaceutical and nutraceutical industries, packaging plays a critical role in ensuring product safety, efficacy, and shelf life. This guide provides a comprehensive overview of glass bottle selection for capsule and pill packaging, tailored for retailers, wholesalers, and distributors. Learn why glass is the preferred material, how to choose the right bottle size, and how Shining Glass can be your trusted partner in pharmaceutical packaging.

넶0 2025-03-11 -

The Genius of Texture: How Beverage Brands Use Orange Peel Patterns to Stand Out

To All Brand Owners, Designers, and Beverage Enthusiasts: Let's Talk About the Orange Peel Texture on Drink Bottles!

Yes, that bumpy, dimpled texture on your favorite drink bottle isn’t just a random design choice. If you thought it was merely decorative, think again! This unassuming feature is the “hexagonal warrior” of the beverage packaging world, a true hidden champion of industrial design that seamlessly blends functionality, aesthetics, and cost-efficiency.넶4 2025-02-28 -

Bottle Neck Finishes: The Unsung Hero of Packaging Innovation

Did you know a bottle’s neck finish can make or break your product’s success? From leak-proof seals to tamper-evident designs, these unsung heroes ensure functionality, safety, and brand appeal. Dive into the critical role of thread standards (GPI, FD), dimensional precision (T, E, H), and innovative closures like DBJ or cork. Discover how material choices and sustainability trends are reshaping packaging—and why mastering these details safeguards your product’s integrity.

넶8 2025-02-21 -

Choosing the Right Wine Bottle Neck and Closure for Your Premium Wine

Wine bottle neck designs vary significantly, each paired with specific closures that suit the wine's type, storage requirements, and target market. Below is an overview of common wine bottle neck types, their compatible closures, advantages, and disadvantages.

넶6 2025-01-04 -

Why Glass Water Bottles Are the Best Choice for Your Beverage Brand

Water is an essential drink, but have you ever wondered why we prefer it in glass bottles? The choice of packaging plays a significant role in preserving water's purity, taste, and health benefits. This article delves into why glass is the ideal material for water, especially sparkling water, and how it compares to plastic and metal alternatives. We'll also explore the environmental and health advantages of glass and guide you on selecting the best glass water bottles for your brand.

넶8 2024-12-19